70% OF ROBOT CORE COMPONENTS

占机器人身体70%以上的核心部件

无论是工业级机械臂,还是仿生机器人,谐波减速器都是重要的核心部件,起到能量放大器的作用,我们在精密谐波减速器的研发和制造方面拥有超过20年的经验,也是众多机器人公司的核心供应商。

HIGHER INDUSTRY STANDARDS

更高的行业标准

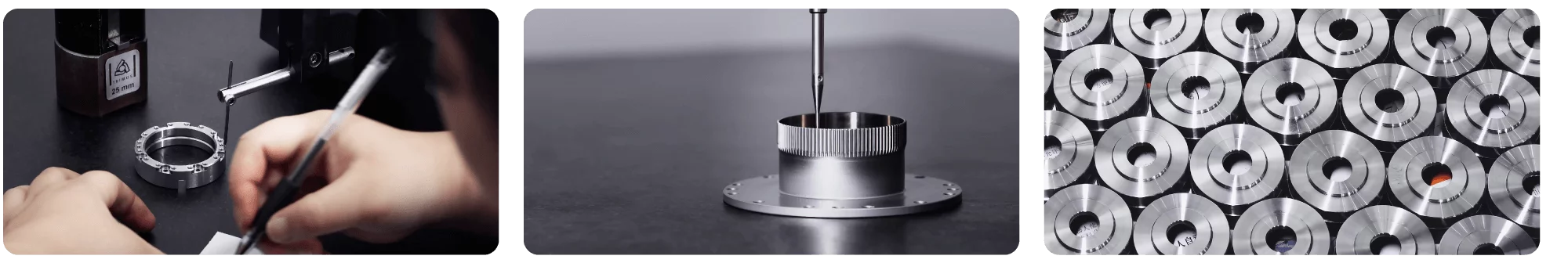

我们了解客户需求,在产品制造过程中执行军工级的行业标准,将每一件产品都当成艺术品来对待,赋予其更长久的生命力。

PRECISION MANUFACTURING

超精密制造

近20年来,我们始终专注于谐波减速器领域的精密制造,在工业自动化和机器人领域为客户提供最优质的产品,我们也是机器人产品中受欢迎的核心部件供应商,客户遍布全球。

超细密ADI材料

我们坚持基础材料研发,攻克多项技术难关,我们采用超细密球铁连铸空心型材经等温淬火得到超细密的ADI材料。其特点:

1. 自润滑;

2. 低温升;

3. 减震降噪;

4. 使用温度范围广;

5. 使用寿命长。

超精密热处理工艺

我们在材料热处理工艺方面经过多年技术沉淀,找到谐波影响疲劳强度的硬度与韧性两个因素之间平衡点的变化规律,结合加工后的应力聚积和加工前的应力消散制定出完善的热处理工艺,且完整付诸量产。

柔轮的特殊工艺

我们在柔轮齿形加工工艺中创新发明了变形后光整加工的方法,在保证精度的前提下解决了传统钢柔轮接触不均匀的问题,使齿面啮合充分接触,受力更均匀、摩擦力小、产品更耐用。

创新发明S齿形设计

我们联合高校深海静音传动实验室就如何平滑传递摩擦力及降低切齿摩擦系数等研究,创新发明了S形谐波齿廓设计理论,并结合运动学、摩擦力学和润滑学等设计了自动生成s形曲线的模拟软件。

刀具自主设计研发

我们创造性地在谐波齿轮的加工中研制前切后压的一体式复合刀具,使得微小型谐波减速机由于刀具制作困难而产生的市场空白迎刃而解,开发出了行业独有的微小型谐波减速机系列产品。

韧性保护

我们通过特殊的电渣重熔净化原材料、反复旋压等精密手段,提高柔轮材料各项性能指标的稳定性,确保柔轮疲劳强度的严苛要求。在过载情况下,材料的延性变形最大程度地保护了整体机械结构免受损坏。